CAPSTIAN TECHNOLOGY

Double Twisting Machine

CAPTIAN's Double Twisting Machine is an equipment used in cable production to twist two or more insulated wires together. This machine can twist wires of different lengths and diameters, providing high efficiency and precision in the twisting process. It is widely used in the production of various cables, including power cables, communication cables, and control cables.

- Machine control by PLC.

- High-speed, high-performance, low-maintenance belt drive.

- Pintles mounted on horizontal shafts, with lubricated “for-life” bearings.

- Loading and unloading through a lifting platform with gearmotor.

- Traversing with an AC servo motor.

- In case of cable break, the coil stops automatically thanks to an air brake.

- With high speed AC motor, self-ventilating, constant torque and thermally protected.

Technical Parameter

SJJ500-800 High Speed Bunching Machine

Technical Parameter

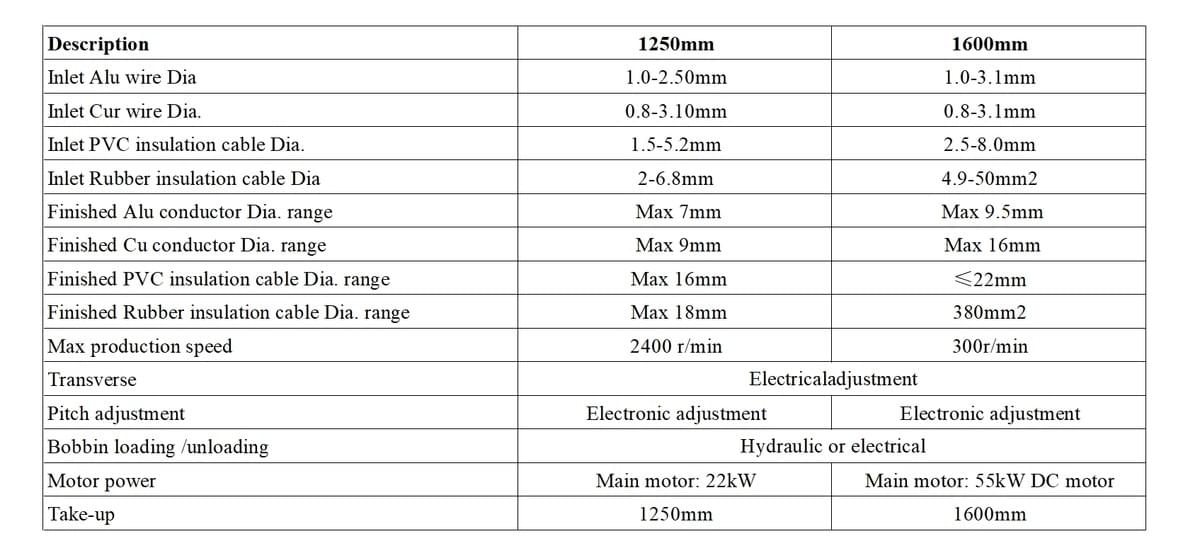

SJJ1250-1600 High Speed Bunching Machine

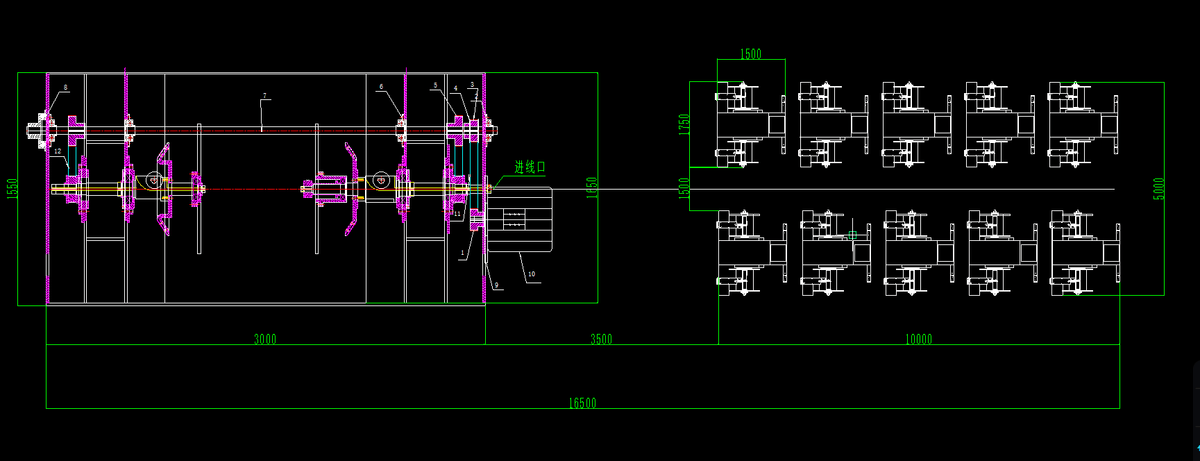

Layout of SJJ800 Wire Bunching Machine With 10 set Active Pay-offs

Φ630mm Double bobbins active pay-off

Pay-off form: active layout

Pay-off reel size: 630mm (customer drawing)

Number of bobbins: 2 bobbins per pay-off, total 20 bobbins(wire)

Input wire range: 0.08mm to 1.2mm

Variable frequency brake, automatic motor adjustment,

Each bobbin driven by independent Yaskawa frequency converter+WMN motor 1.2KW.

Automatic stop and alarm when wire broken.

Control type: Synchronize with the main machine

Tension control: Pneumatic tension

1+6+12 Double foaming wire plate

After all wires are released from the pay-off, they enter the distribute plate through a group of guide wheels, and then enter the eye mold for stranding.

Specification of input wire eye mold: (outer circle) Ø 25 * (height) 15 inner hole( according to customer requirements)

Equipped two foaming wire plate.

Equipped double pulley equitensor straighten device:1 set

Φ800 high speed buncher

1) Model:

Right head: The person faces the front of the machine, and the wire enters the machine from the right side of the machine.

2) Bow rotation speed: Max: 1200RPM. The bow is a guide wheel type.

3) Laying length: 22.51mm-152.32mm (can be adjusted appropriately according to customer needs), manual gear type change of twisting length.

4) Calculation of stranded wire length: MPM= Ptich* 2/1000 * RPM

5) Twisting direction: S or Z

6) Input wire diameter: Ø0.35mm-Ø4.0mm

7) Stranding diameter: Ø1.85mm-Ø15.0mm (max 16mm2 for copper wire and 25mm2 for aluminum wire).

8) Traverse: German-style bearing polished rod arrangement and adjusted.

9) Main shaft lubrication: manual grease gun to fill in oil.

10) Drive motor: AC 440V 1400RPM 15HP Shanghai Jinzhengcheng motor + Inovance inverter stepless speed regulation.

11) Braking: electromagnetic brake, automatic braking when internal and external broken wire.

12) Broken wire protection: If the internal or external disconnection, the machine will automatically stop and alarm.

13) Jog: PLC touch screen display.

14) Speed display: PLC touch screen display.

15) Electrical control: Inovance PLC control system, and the touch screen is Inovance. Parameter setting and operation are all set through the PLC touch screen control panel.

16) External power cord: The external power cord is pulled by the user to the electric control box.

17) Alam light: two-color.

18) Meter counter: PLC touch screen display.

19) Electrical components: Select domestic and international high-quality brands.

20) Bearings: Use imported bearings from Japan, Germany, etc. (such as KOYO; NSK; FAG).

21) Internal parts of the machine: Select domestic and international high-quality brands.

22) Machine noise: below 75dp, measured at a distance of 1000MM.

23) Ambient humidity: cannot exceed 90%. If it exceeds, please blow dry first and then turn on the machine.

24) Workshop temperature: cannot exceed 40℃. If it exceeds, the inverter will automatically trip for protection.

25) Box color: blue (according to customer requirements)

Take-up structure:

1) Take-up bobbin: Standard: (OD) Ø800* (outer width) 600* (inner hole) Ø80, the extraction pin hole is Ø40, and to distance from the shaft hole, The max center is 160mm and the min is 120mm (the take-up can also be customized according to customer requirements).

2) Tension: 5KG magnetic powder clutch is used to automatically control the tension.

3) Bobbin loading and unloading: electric lifting

Double Twist Bunching Machine: Efficient Stranding for Small and Large Cross-Section

Copper and Aluminum Strands

Get Quotation Hear

Capstian Technology Provice High Quality Wire Buncher Machine

Chinese Cable Extrusion Line

Chinese Single Twisting Machine

Chinese Wire Bunching Machine

Address: No.401, #34 Bingjiangxincun,Yangming Street, Yuyao, Ningbo,China

Proudly built with Ningbo Capstian Technology Co.,Ltd.